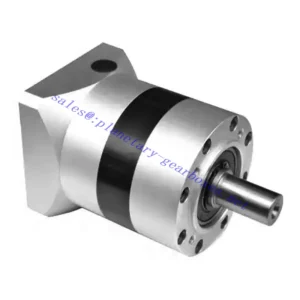

Spur planetary gearbox

As one of the planetary gearbox manufacturers, suppliers, and exporters of mechanical products, We offer planetary gearboxes and many other products.

Please get in touch with us for details.

Mail:[email protected]

Planetary Gearboxes

Planetary gearboxes are a type of gear system that uses planetary gears to transfer torque and rotational speed between input and output shafts. They are known for their compact size, high power density, and precision motion control, making them an ideal solution for a wide range of industrial and automation applications.

A planetary gearbox is a type of gear reducer that uses a series of gears arranged in a planetary configuration to achieve a high gear ratio in a compact package. The planetary gearbox consists of three main components: sun gear, planet gear, and ring gear. The sun gear is the central gear that is driven by the input shaft. The planet gears are mounted on a carrier that rotates around the sun gear. The ring gear is the outer gear that is the output of the planetary gearbox

Planetary Gearboxes Specifications

|

Stage

|

stage 1

|

stage 2

|

stage 3

|

|||

|

Contains the speed ratio

|

3 4 5 7 10

|

12 16 20 25 28 35 40 50 70 100

|

80 100 125 140 175 200 250 350 400 500 700 1000

|

|||

|

A

|

B

|

A

|

B

|

A

|

B

|

|

|

Length(mm)

|

56

|

154.5

|

80

|

178.5

|

104

|

202.5

|

|

Rated Input Speed(rpm)

|

3500

|

3500

|

3500

|

|||

|

Maximum Input Speed(rpm)

|

6000

|

6000

|

6000

|

|||

|

The Maximum Radial Force(N)

|

1020

|

1270

|

1420

|

|||

|

The Maximum Axial Force(N)

|

850

|

1100

|

1250

|

|||

|

No Load Torque(Nm)

|

about0.8

|

about0.4

|

about0.4

|

|||

|

Efficiency withfull load(%)

|

96

|

94

|

90

|

|||

|

Backlash(arcmin)

|

standard <10

|

standard <15

|

standard <22

|

|||

|

Noise(dB)

|

≤62

|

≤62

|

≤62

|

|||

|

Weight(Kg)

|

2.8

|

3.4

|

4.0

|

|||

|

Average lifetime(h)

|

>20000

|

|||||

|

Torsional Rigidity(Nm/arcmin)

|

7.5

|

|||||

|

Lubricant

|

Effective lubrication

|

|||||

|

Direction of rotation

|

the input and output to the same

|

|||||

Planetary Garboxes Benefits

High torque density: Planetary gearboxes can achieve a high gear ratio in a compact package, making them ideal for applications where space is limited.

High efficiency: Planetary gearboxes are very efficient, typically achieving efficiencies of 90% or higher.

Long life: Planetary gearboxes are very durable and can withstand high loads and shock.

Smooth operation: Planetary gearboxes operate smoothly and quietly, making them ideal for applications where noise is a concern.

Compact size and light weight: Planetary gearboxes are typically smaller and lighter than other types of gear reducers, making them ideal for applications where weight and space are a concern.

Wide range of applications: Planetary gearboxes can be used in a wide variety of applications, including robotics, machine tools, 3D printers, automated guided vehicles (AGVs), packaging equipment, medical devices, food and beverage processing, and aerospace.

Uses Of Planetary Garboxes

Robotics: Planetary gearboxes are used in robotics to provide high torque and speed reduction in a compact package. This allows robots to perform a wide range of tasks, such as lifting heavy objects, moving quickly, and making precise movements.

Machine tools: Planetary gearboxes are used in machine tools to provide high torque and speed reduction for spindles and other rotating components. This allows machine tools to perform a variety of operations, such as cutting, drilling, and milling, with high precision and efficiency.

3D printers: Planetary gearboxes are used in 3D printers to provide high torque and speed reduction for the print head. This allows 3D printers to print complex objects with high accuracy and detail.

Automated guided vehicles (AGVs): Planetary gearboxes are used in AGVs to provide high torque and speed reduction for the drive wheels. This allows AGVs to move heavy loads quickly and precisely in a variety of environments.

Packaging equipment: Planetary gearboxes are used in packaging equipment to provide high torque and speed reduction for conveyors, motors, and other rotating components. This allows packaging equipment to operate efficiently and reliably.

Maintenance tips for Planetary Garboxes

Check the oil level and condition regularly. The oil in a planetary gearbox helps to lubricate the gears and prevent wear. The oil level should be checked regularly and topped up as needed. The oil should also be checked for signs of contamination, such as dirt, debris, or water. If the oil is contaminated, it should be replaced.

Inspect the gears for wear and damage. The gears in a planetary gearbox are subject to wear and tear. The gears should be inspected regularly for signs of wear, such as scoring, chipping, or cracks. If the gears are damaged, they should be replaced.

Lubricate the gears properly. The gears in a planetary gearbox should be lubricated properly to prevent wear. The type of lubricant used will depend on the operating conditions of the gearbox. In general, a high-quality, high-viscosity lubricant should be used.

Keep the gearbox clean and free of debris. Debris can enter a planetary gearbox and damage the gears. The gearbox should be kept clean and free of debris by regularly cleaning the exterior of the gearbox and the air intakes.

Inspect the seals for leaks. The seals in a planetary gearbox help to prevent oil leaks. The seals should be inspected regularly for leaks. If the seals are leaking, they should be replaced.

Have the gearbox serviced by a qualified technician regularly. A qualified technician can inspect the gearbox and identify any potential problems. The technician can also make any necessary repairs or adjustments to the gearbox.

We are one of the best planetary gearboxes manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!